SOLUTIONS

- Preparation of technical specification with the minimum technical requirements for an electrical machine solution of the highest quality.

- Preparation of technical specification of the complete machine or its components which need rehabilitation, refurbishment or uprating.

- Preparation of technical specification of spare parts for replacement in the electrical project.

- Electromagnetic calculation of the electrical machine based on customer requirements, international standards, power system and turbine data as output, the basic study of the electrical machine with all the characteristics already defined power, voltage, efficiency, temperature rises, reactances stator and rotor dimensions, weights, among others.

- To issue the electrical machine data sheet, characteristic curves, winding diagram, among other relevant documents part of the electrical machine design.

- Reverse engineering of machines in rehabilitation, refurbishment or uprating from existing machine data, such as original drawings and commissioning test reports.

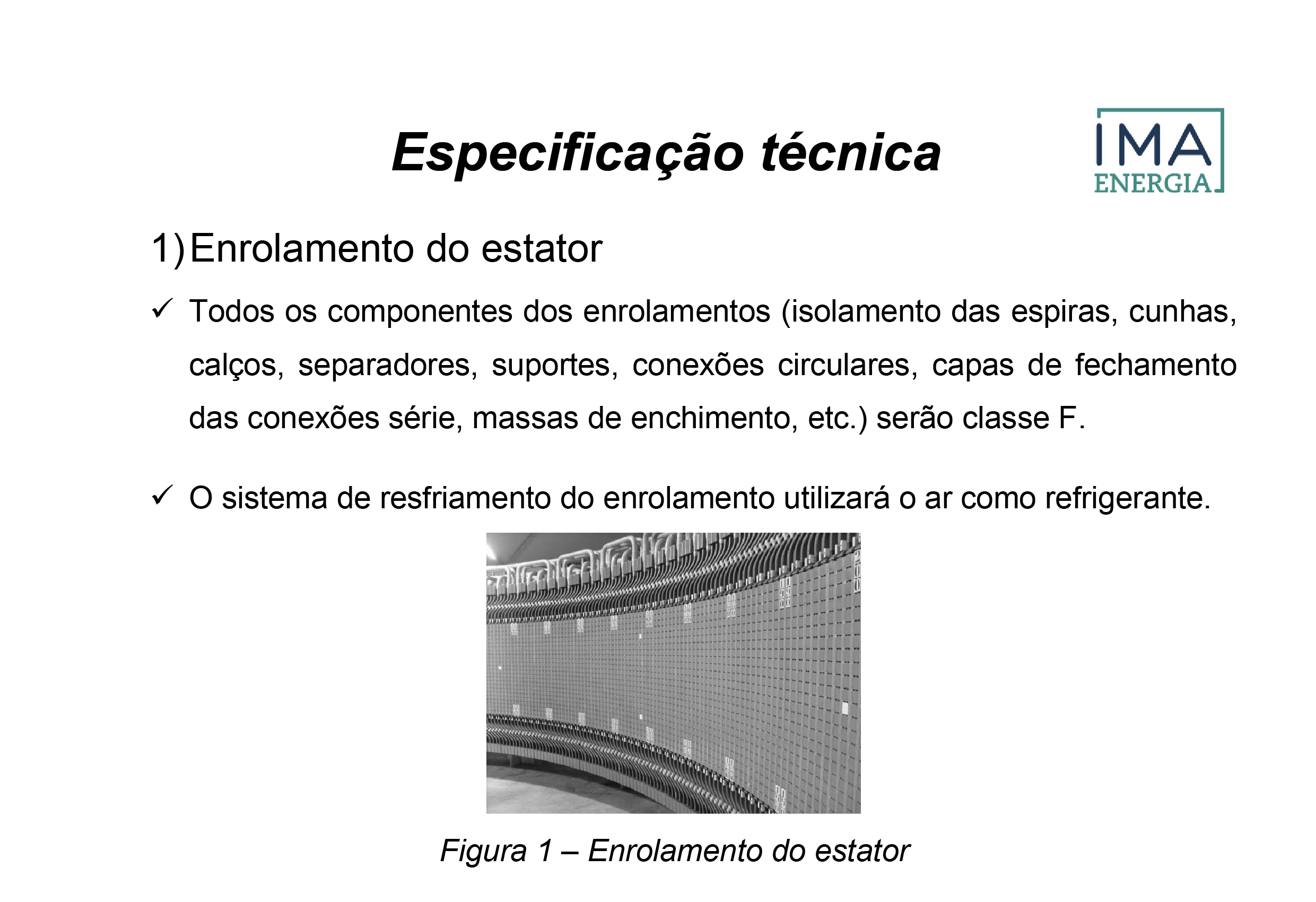

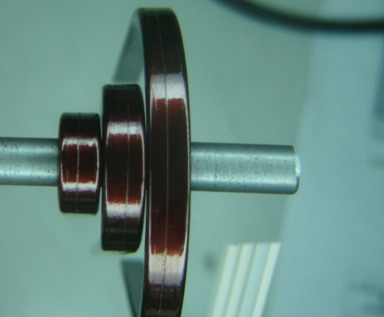

- To design the stator and rotor insulation system, using the state of the art on materials and on manufacturing processes.

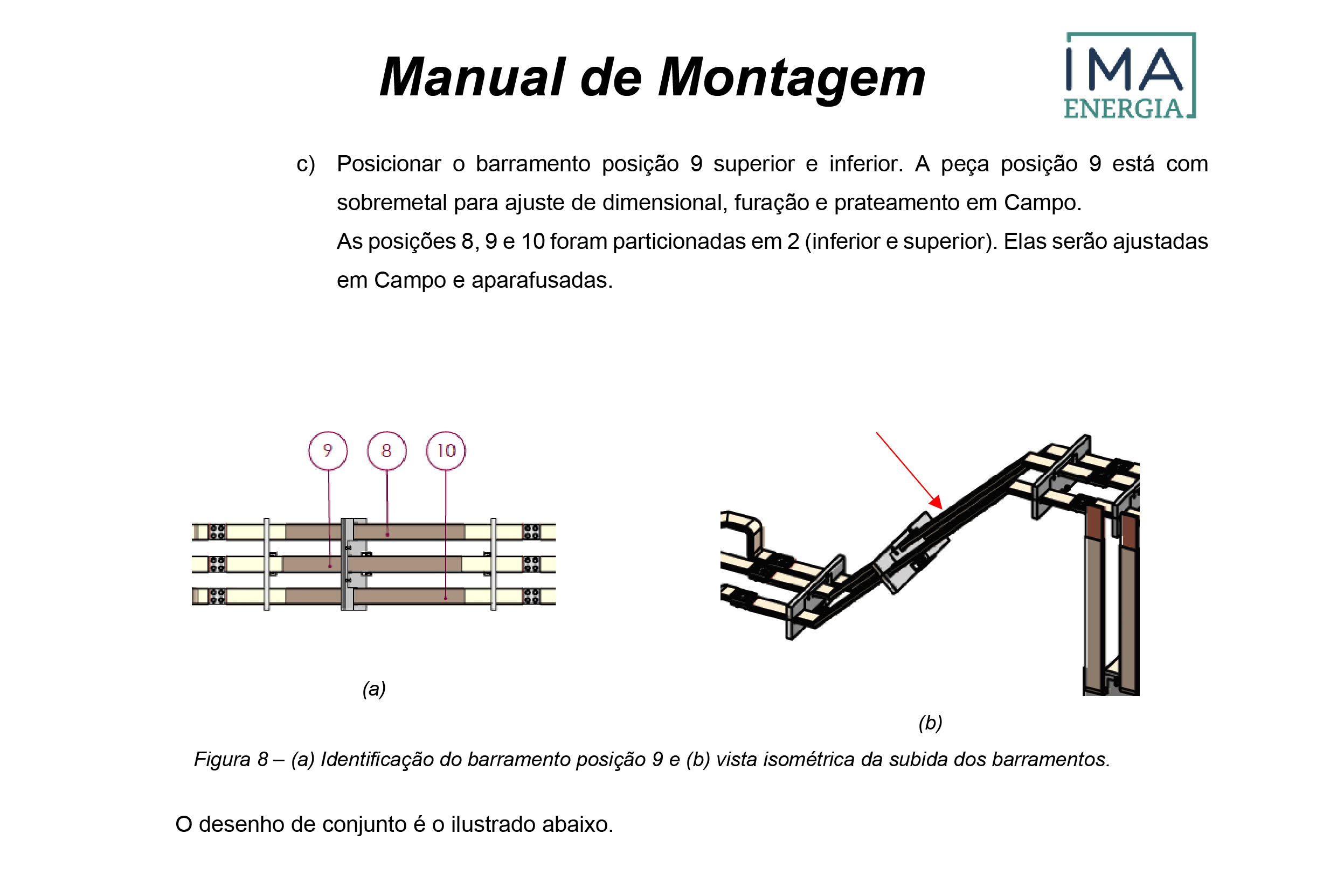

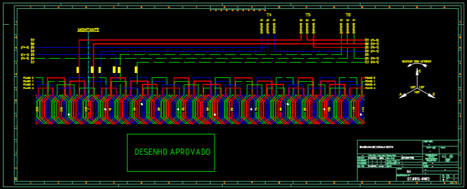

- Preparation of assembly manuals, operation & maintenance manuals (O&M) and commissioning manual of the electrical machine using the best practices.

- Analysis and checking of drawings, bills of materials, technical manuals, manufacturing instructions and other relevant documents to the electrical machine design.

- Interface discussions of the electrical machine with auxiliary systems such as excitation, instrumentation and shielded bus.

- To propose improvements on electrical machine design, manufacturing and assembly.

- Root cause analysis of failures on the electrical machine, whether due to an electrical event (ground fault, short between turns), mechanical (vibration, cracks), thermal (temperature distribution, ventilation circuit) and the environment (oil contamination of the bearing or brush powder) with the preparation of a complete report based on the sequence of events and the damages observed on the electrical machine.

- Solution propositions for the machine repair or complete rework.

- Performing and or following inspections in the workshop or field to release the manufacturing of the parts, final approval of parts for shipment or release for the next field activities, based on the inspections described in the inspection and testing plan or in commissioning manual of the electrical machine.

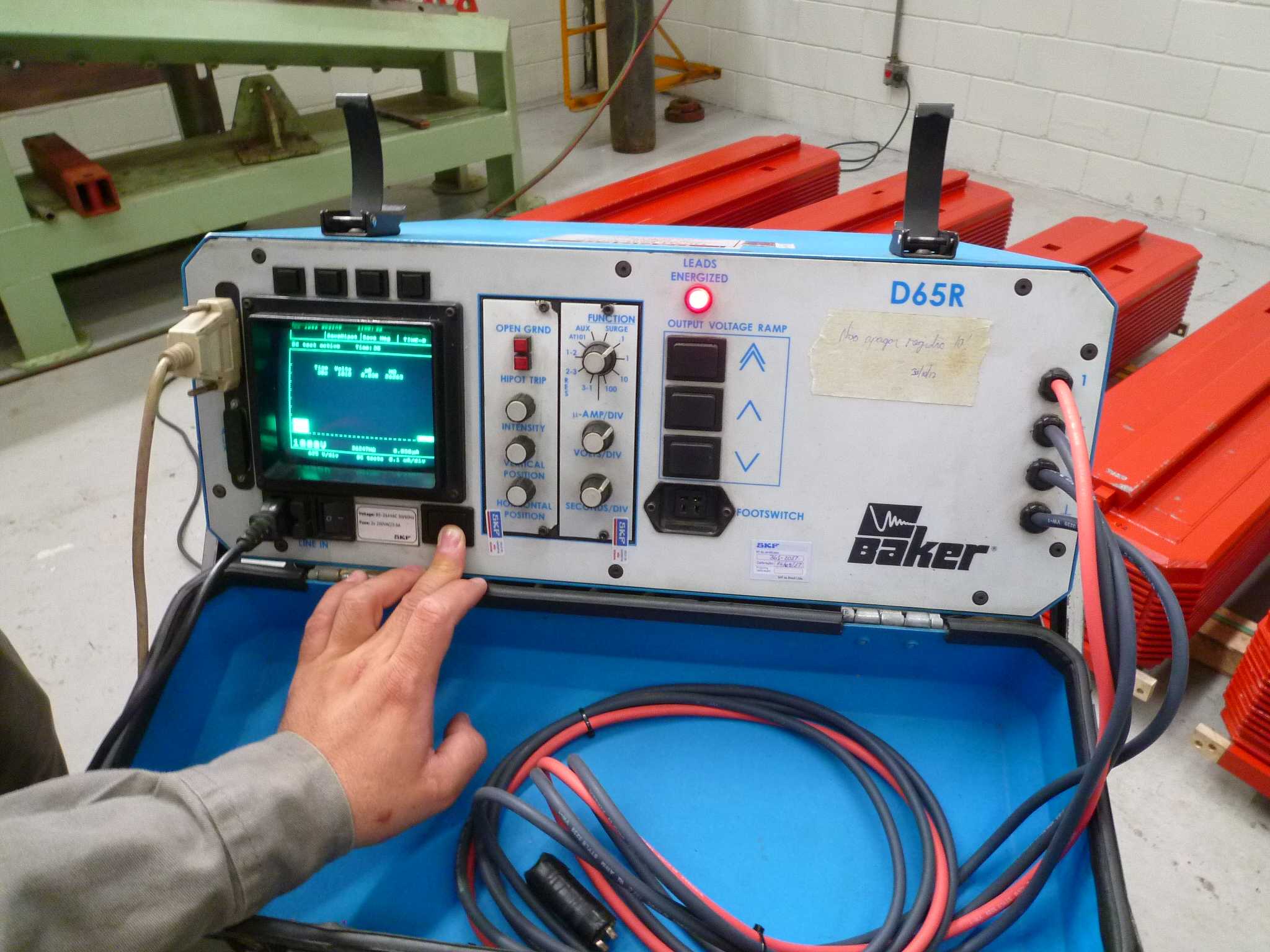

- Following of workshop or field electrical tests for manufacturing release of the parts, final approval of parts for shipment or release for the next field activities, based on the inspections described in the inspection and testing plan or in commissioning manual of the electrical machine.

- To propose minimum technical criteria for testing, taking into account international standards and best design and manufacturing practices.

- Indication of the state of the art materials and manufacturing processes applied on active parts of electrical machines: stator laminations, stator bar or multi turn coils, pole coil, pole body and stator or rotor connections.

- Preparation of the testing plan qualification of new materials and of manufacturing processes.

- Performing and/or supervising material development activities and process qualification.

- Contacting material suppliers to request samples, adjust material features as required by the customer and collect quotation for equipment on the manufacturing process.

- Electrical, mechanical and insulation aspects of synchronous machines.

- Design, manufacturing, assemly, operation & maintenance of synchronous machines.

- Insulation technologies.